Hygienic line

알파라발의 Hygienic 라인은 식품, 음료, 제약 등 위생 공정에 특화된 프리미엄 열교환기입니다. 뛰어난 에너지 효율성으로 제조 공정에서 발생하는 탄소 배출량을 절감합니다.

Hygienic heating and cooling for maximum product safety, uptime and energy efficiency

- Enhanced product safety due to unique design features on plates and gaskets

- Superior cleanability due to innovative plate pattern for enhanced hygiene

- Longer run times between cleaning cycles thanks to optimized media distribution

- High heat transfer efficiency, minimizing the use of energy and materials

- Straightforward maintenance with easy access and ClipGripTM gasket attachment

Accelerate sustainability with the Alfa Laval Hygienic line. These premium plate heat exchangers have been developed with a focus on hygiene and reducing the use of energy, water and cleaning media.

Optimized flow distribution and a smoother plate pattern improve heat transfer efficiency, improving energy efficiency by up to 15%. These features also contribute to lowering the pressure drop by up to 10% while enabling the heat exchanger to perform the same duty.

Using 10% less steel, on average, to produce the unit compared to previous models reduces the carbon dioxide (CO2) emissions embedded in the product in a similar way. Durable and energy-efficient, these hygienic plate heat exchangers help reduce the environmental footprint of hygienic applications in food and pharma manufacturing.

The streamlined SmoothPortTM prevents buildup and maximizes cleanability and drainability.

EquiflowTM optimizes media flow, enabling uniform heat treatment with minimal fouling.

Hygienic line heat exchangers - Innovating hygienic performance

Minimized fouling, superior cleanability, and simplified maintenance. All come together in Alfa Laval Hygienic line—a complete range of premium heat exchangers with unparalleled hygienic performance.

Improving cleanability and service

After many years of supporting food and beverage manufacturers, Palle Melchart understands the importance of cleanability and easy service in hygienic heating and cooling.

How Alfa Laval Hygienic line plate heat exchangers work

The space between the plates forms channels. The ports at the top and bottom of the plate enable two different media to flow through alternate channels. The hot media flowing in one channel transfers heat through the thin plates to the cold media in the other channel. Counter-current flow makes it possible to achieve the highest heat transfer efficiency.

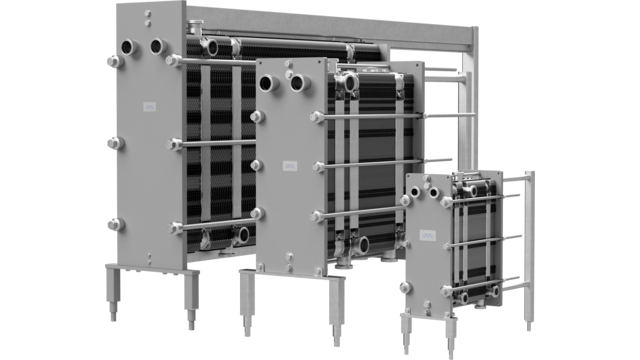

Several hygienic heat exchangers are combined in the same frame using connection plates for certain process steps, such as pasteurization. Using several connection plates enables the creation of additional sections. If a redesign is required, changing the inlet and outlet of these connection plates is easy.

Alfa Laval 위생 액체/액체 GPHE

Alfa Laval 멀티 섹션 저온 살균기 GPHE

멀티 섹션 위생 GPHE

Products - Hygienic WideGap

The Hygienic WideGap was engineered specifically for fluids containing fibres and particles. This innovative technology enables impressive energy savings and heat recovery, surpassing the limitations of traditional shell and tube heat exchangers. Designed for food processing applications, the hygienic WideGap is perfect for a wide range of products, ranging from pulp-filled juices and purées to crushed tomatoes, dressings, and even plant-based beverages.