Technical information - Compabloc heat exchanger

Alfa Laval is the only supplier of bloc-type heat exchangers with more than eight decades of experience developing heat transfer technology. All of that expertise has gone into making Compabloc the unrivalled champion of heat exchange – with unique innovations that set it apart from the rest.

How does Compabloc work

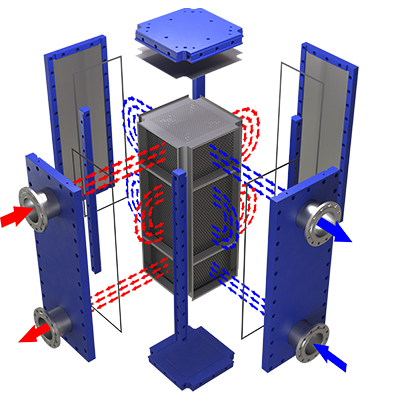

Sitting at the core of every Compabloc is a stack of corrugated heat-transfer plates made of stainless steel or other corrosion-resistant materials, laser welded alternately to form channels.

The hot and the cold streams flow through alternate channels. Corrugated plates cause high turbulence, resulting in substantially higher heat transfer efficiency with a 50–80% smaller heat transfer area than comparable shell-and-tubes. Flow turbulence also reduces the build-up of fouling. The Compabloc’s unique plate design eliminates dead zones in the heat exchanger.

The two flows in a Compabloc can be configured as single pass, or as multiple pass by using baffles. The number of passes on the hot and cold side can be chosen independently, making it possible to optimize heat transfer even if flow rates on the different sides differ greatly. This unique flexibility means the Compabloc is always optimized for exactly the required duty. The baffles are made to withstand full vacuum, and can be rearranged if design conditions are changed in the future.

Compabloc units have a counter-current flow and can operate with a crossing temperature program (in a single unit), where the temperature approach is as close as 3°C (5.4°F), maximizing energy recovery. The small size and light weight makes it possible to install Compablocs anywhere, for instance at the top of distillation columns or suspended from support structures.

Compabloc - 싱글 패스 콘덴서

Compabloc - 투패스 콘덴서

Compabloc 액체-액체

Compabloc 재가열기

Compabloc unique features

C-Weld™

Superior cleaning and extended performance

Alfa Laval manufactures the Compabloc plate pack using advanced laser welding with a butt-to-butt weld joint technique known as C-Weld. This eliminates crevices or “dead zones” common in other bloc-type heat exchangers, where fouling can build up, leading to corrosion and failure.

The use of laser welding and the C-Weld joint design further ensure higher reliability than conventional weld techniques, such as lap weld joints or TIG welding, which are far more susceptible to mechanical stress and failure. The end result is increased reliability and serviceability for maximum uptime.

SmartClean™

Fast and efficient flushing of fouling material

Alfa Laval’s C-Weld manufacturing method creates open channels around all the edges of plates in the Compabloc plate pack. During mechanical or chemical cleaning, as well as in the course of regular operation, any fouling that occurs will move along the heat transfer surface and flow freely out of these channels at the plate boundary. This SmartClean design makes it possible to fully clean every plate in the unit, returning the Compabloc to like-new performance after maintenance.

The SmartClean channels, impossible on bloc-type heat exchangers manufactured with edge welding, makes regular cleaning of the Compabloc both simple and quick.

+Seal

Confident, long-term performance under pressure

Unlike traditional flat gasket designs, +Seal introduces the first fully confined graphite gasket in a bloc-type heat exchanger. This prevents the risk of media leaks at pressures as high as 60 bar, simplifies maintenance, and protects against overtightening and creeping.

This is part of our revolutionary new Compabloc+ and is the secret to reaching higher design pressures without compromising on safety.

XCore™

Advanced design for higher pressures

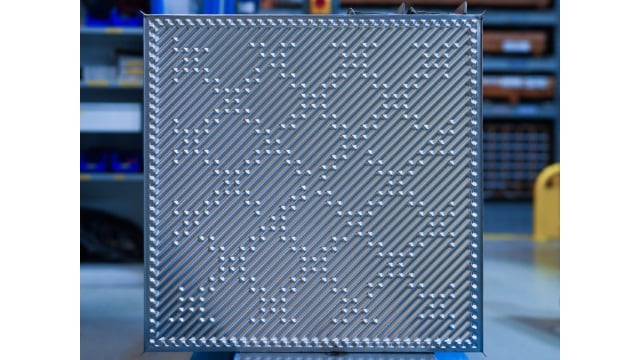

Compabloc plates feature a one-of-a-kind pattern with “half-pyramids” equally distributed across the plate in an X-shaped pattern. This adds rigidity that increases mechanical strength for superior resistance to elongation forces common in high-pressure applications. With this cleanable XCore pattern, certain Compabloc models can handle pressures up to 42 barg without compromising thermal performance.

6 considerations for your selection process

Discover the plate heat exchanger benefits of Alfa Laval Compabloc

입증된 신뢰성

사람들이 Alfa Laval Compabloc을 선택하는 이유는 간단합니다. 제대로 작동하고, 이미 30,000대 이상 판매된 실적이 있기 때문입니다. 여기에 Alfa Laval의 입증된 제조 솔루션과 기술 솔루션이 우수한 신뢰성과 긴 작동 수명을 보장합니다. 수십 년간 쉬지 않고 작동해 온 Compabloc 중 대부분이 아직도 최고의 성능을 발휘하고 있습니다.

지속 가능성 향상을 위한 솔루션

열 효율이 높은 Compabloc을 열 회수에 이용하면 열 회수율이 높아지고, 보일러 연료 소비량이 줄어들고, CO2 배출량도 감소합니다.

몇 개월 안에 투자 회수

높은 에너지 효율과 저렴한 설치 및 유지보수 비용이 합쳐진 Compabloc은 shell-and-tube 열교환기나 기타 용접식 판형 열교환기 등 다른 기술에 비해 투자금 회수 시간이 훨씬 짧습니다. 몇 개월 안에 장비 구입 비용이 회수되는 경우도 종종 있습니다.

생산량 증가 및 설치비 절감

가열이나 냉각과 관련된 병목 현상은 흔히 보다 효율적인 열교환기로 해결할 수 있습니다. Compabloc은 크기가 작아 동일한 공간에 훨씬 더 강력한 성능을 담을 수 있고, 아니면 다른 종류의 장비를 위한 여유 공간을 확보할 수 있습니다. 따라서 설치 비용도 적게 듭니다.

Ready for any duty

Compabloc is available in a wide range of sizes and is custom made to fit the specific operating and installation conditions. It can be made in virtually any material that can be pressed and welded.

Simplified maintenance for higher performance

Minimized fouling allows Compabloc to operate with cleaning intervals substantially longer than traditional heat exchangers, reducing lifetime maintenance costs. It is also the only welded heat exchanger where all channels, both hot and cold, can be fully cleaned using a hydro jet, bringing performance back to 100% after every cleaning.

HEXpert selector tool

Quickly find the ideal welded plate heat exchanger for demanding process applications. Fill in information about your duty, and within five minutes you can explore a customized recommendation for an efficient thermal solution.